update:2016-07-19 00:00:00

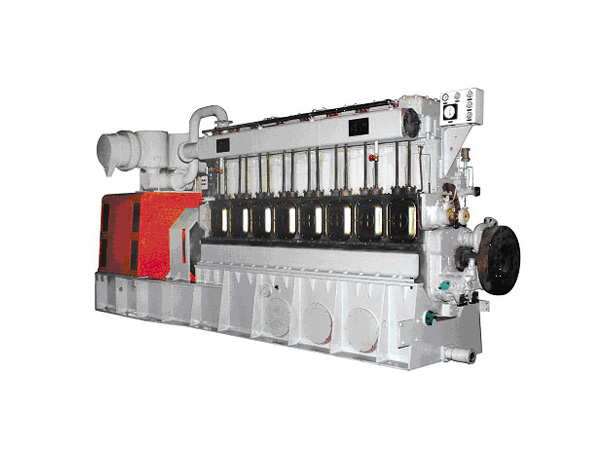

series:300 series gas engine

300 series gas engine:

china's coal-bed methane (commonly known as gas) is very rich in resources, below the surface, more than 2000 meters in depth of coal ranks layer contains a quantity of 35 trillion cubic meters of gas, basic and china's natural gas resources in the amount, equivalent to 420 million tons of standard coal, 2006 china has included in the "eleventh five year" plan for energy development and development of coalbed methane, coal-bed methane industry development has ushered in a good opportunity for development.

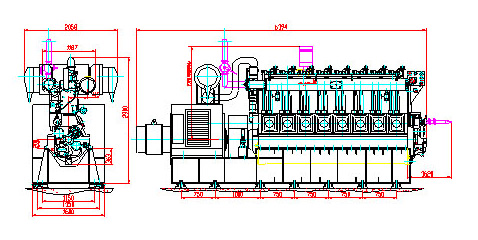

the 300 series gas engine is zibo zichai new energy co., ltd. is the independent research and development of gas engine, to coal mine gas as the main fuel, technology advanced. the features of compact structure, easy operation, reasonable arrangement, easy maintenance, etc..

each type of unit is mainly used in land power generation, the frequency can be divided into 50hz, 60hz, can be single unit operation can also be multiple units in parallel operation. has been widely used in major coal mines in china.

technical characteristics:

(1) the advantages of large diameter and long stroke, power reserve, suitable for large fluctuations in coal seam gas source, to ensure sustained and constant power output.

(2) to adapt to a wide range of gas concentration, low concentration of the advantages of the unit.

(3) generator speed low, reduce engine wear, prolong the service life of the parts, reduce spare parts reserve;

(4) the development of the gas engine intelligent management system, can ensure the safe and efficient operation of the gas engine, and can realize the remote monitoring of the gas engine group.

(5) the coal-bed gas engine by means of electronic control, realization of gas engine air although ratio and optimum ignition advance angle of real-time control, through monitoring the detonation achieve ignition advance angle optimal control and make the engine work in the best condition to prevent engine deflagration, an air inlet pipe tempered, exhaust pipe blasting and other issues, but also improve the dynamic property and economy of the engine.

(6) the exhaust pipe adopts the water cooled structure, the exhaust temperature is low, the combustion is full, the temperature of each cylinder is uniform.

(7) using the american altronic company to produce the ignition system, in order to obtain high ignition energy and precise ignition time, to ensure the safety and reliability of ignition.

(8) set up a multi-channel line of defense to ensure the safety of the coal seam gas pipe line.

(9) design waste heat utilization system, make full use of high temperature flue gas heat, realize the combined heat and power supply, so that the total heat utilization rate of the burning gas to reach more than 70%;

(10) can be high, medium and low voltage output, in order to meet the various needs of users, to avoid the initial investment of the transformer to reduce the loss of copper, reduce operating costs;

conditions of use:

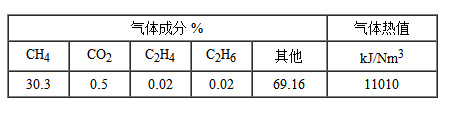

(1) the gas composition and calorific value of coal bed gas are as follows:

(2) coal bed gas source conditions:

gas delivery pressure 5 ~ 15kpa and pressure change rate is less than or equal to 1kpa/min, change rate is less than or equal to 5%/min; impurity particle size less than or equal to 5 m, impurity content is less than or equal to 30mg / nm3, water content is less than or equal 40mg/nm3, not containing free water, the gas temperature is less than or equal to 40 deg c sulfur is equal to or less than 20mg / nm3.